What Does EGL AvDesign Do ?

EGL Avdesign Inc. working in close association with a Transport Canada Design Approval Representative (DAR); will provide all the Approved Data that complies with the Type Certification requirements of your aircraft. In plain talk - we will provide the aircraft operator with all the structural repair (or modification) paperwork necessary to release the aircraft back into service. Understandably, most repairs are found in the Aircraft Maintenance Manual (AMM); Aircraft Structural Repair Manual (SRM); or other places - but ... these repairs may not always be what the operator is looking for. Some repairs call out materials, fasteners, or processes that are not obtainable or possible in your situation today. Some repairs are unrealistic with the extensive work scope required to satisfy the conditions. Other repairs just take too long to obtain from the Manufacturer! We are the alternative solution! Working with us allows you to gather your materials; organize your technicians and proceed with preliminary work while we simultaneously design and work out the repair details. We will ask questions like .. What repair materials do you have in stock? What fasteners do you have on hand? Can you perform heat treating? How extensive are your metal forming capabilities? We use this information to tailor the repair design to your situation! Last minute findings - again not a problem; seen it all before!

In some cases - dealing with the Aircraft Manufacturer (OEM) - can be like playing "Russian Roulette" - nobody is informed of the repair details until the repair "just shows up". This will inevitably cause AOG material purchases; hot-shot cross-country shipments, or just unexpected cost overruns and delays. We, on the other hand, provide a controlled atmosphere based on collaboration and tailoring the repair to your capabilities and material inventory. With us providing you some advance notice - most of the painful issues can be avoided. This will SAVE you time and resources! .. We are also in sync with subcontractors who stock repair materials & fasteners and would be able to supply. We avoid materials that are difficult to obtain for our repairs. We pride ourselves for finding alternatives and for 'thinking outside the box'!

What We are Good At ?

We can also do Supplemental Type Certificates (STC) and Product Design Approvals (PDA) ... but we only do these on slow rainy days! What we are best with is dealing with the customer on a "one-on-one" basis - hashing out repair details with the on-site technician. Find out if you just require a repair - or just some guidance. When you have a concern, pick up the phone and call us? We just love dealing with Repairs! If we happen to be aware of an OEM generic repair that will take care of your issue - No Charge. We have seen most of it somewhere or know of someone who did. We even deal with the OEM directly - because we had worked there at one time designing repairs! We are not shy with giving you the solution today. If you require expert technicians or services like NDT - we know of subcontractors ready to help out anywhere in the country. We are aware that you require an answer immediately because your high-priced technicians are standing around looking at you for something to do and the ops manager never stops ringing your phone!

We are Engineers

We do not to operate rivet guns and bend metal anymore - instead we use our experience seeking timely solutions to difficult problems. We can justify a greater range of options than the Manufacturer (OEM) can. Why? The manufacturer can only select from a limited range of repairs or materials that they have developed or have approved in-house. They will avoid unfamiliar fasteners, repair materials, or processes. But since we have dealt with a large variety of aircraft and situations - we are more familiar with uncommon repairs and odd materials. This allows us a greater latitude in seeking a solution that may work for you !

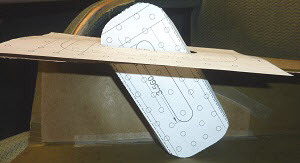

Not all concept verifications need to be complicated

Simple trial using scaled cardboard parts to determine if Repair Doubler can be inserted and positioned inside a small bay of fixed dimensions with no external access. Otherwise the entire external skin panel had to be replaced. A flush repair was required.